Wire types and sizes

Question 1:

Most electrical wire is covered in a rubber or plastic coating called insulation. What is the purpose of having this ïnsulation" covering the metal wire?

Notes:

Not only is this question practical from the standpoint of understanding circuit function, but also from the perspective of electrical safety. Why is it important for wires to be insulated? Are overhead power lines insulated like the wires used in classroom projects? Why or why not? How were electrical wires insulated before the advent of modern plastics technology?

Question 2:

In the early days of electrical wiring, wires used to be insulated with cotton. This is no longer accepted practice. Explain why.

Notes:

This question affords the opportunity to discuss electrical safety with regard to clothing (often made of cotton). Does dry clothing offer insulation to electricity like the old-style cotton wire insulation? Can cotton clothing be trusted to insulate you safely from hazardous voltage?

Question 3:

Electrical wire is often rated according to its cross-sectional diameter by a gauge scale. Which is the larger-diameter wire size, 14 gauge or 8 gauge?

Notes:

For students familiar with shotguns, the methodology of the wire gauge scale makes sense. For just about everyone else, the gauge scale seems "backward."

Question 4:

In the Unites States of America, an organization known as the National Fire Protection Association, or NFPA, publishes an important set of standards called the National Electrical Code. What type of information is contained in this set of standards?

Notes:

NEC code books are rather large, so students may feel inclined to limit their answers to what is included in the Änswer" for this question. However, you should challenge them to look deeper into an NEC book and discover the wealth of information contained therein.

Specifically, ask them to describe some of the Ärticle" topics typically found in an NEC book.

Question 5:

Describe the difference between solid and stranded wire types.

Notes:

A good follow-up question to this would be to ask, "What are some of the advantages and disadvantages of solid versus stranded wire?" Challenge your students to consider such issues as cost, physical flexibility, and ease of connections.

Question 6:

Suppose you pick up a piece of electrical wire and notice this label printed on the insulation:

14 AWG MTW

What does this label tell you about the wire?

Notes:

It is important that students know where to look for information like this, because they will surely come across unique wire types in their later experience, and will need to know how to identify the wire.

Question 7:

What is meant by the ampacity rating of a wire? What criteria establish the ampacity rating of any given wire?

Notes:

Be sure to ask your students what resource(s) proved helpful in researching the answer to this question. Being essentially a safety issue, there are several industry publications on electrical safety regulations that may prove informative.

This question connects several important principles together: physical ratings of materials, power dissipation in metallic conductors, and electrical safety. Challenge your students to "connect" these principles on their own by probing their knowledge with follow-up questions.

Question 8:

Examine the following American Wire Gauge table. Please note that most of the odd-numbered gauges have been omitted, because the even-numbered gauges tend to be more common:

-

Gauge # Diameter (inches) Area (circular mils)

4/0 0.4600 211,600

3/0 0.4100 168,100

2/0 0.3650 133,225

1/0 0.3250 105,625

1 0.2890 83,521

2 0.2580 66,564

4 0.2040 41,616

6 0.1620 26,244

8 0.1280 16,384

10 0.1020 10,404

12 0.0810 6,561

14 0.0640 4,096

16 0.0510 2,601

18 0.0400 1,600

20 0.0320 1,024

22 0.0253 640.1

How many gauge numbers must you increase to (approximately) double the diameter of any given wire gauge? What effect does the doubling of diameter have on the cross-sectional area of the wire?

Notes:

Wire gauge numbers and diameters for this table were taken from table 2-85 of the American Electrician's Handbook (eleventh edition) by Terrell Croft and Wilford Summers. Area in circular mils for each AWG size was calculated from the given diameter.

Question 9:

How many gauge American Wire Gauge sizes must you increase to (approximately) double the ampacity of any given wire gauge?

Notes:

Although this rule is only approximate, it is useful to know!

Question 10:

Describe what electrical conduit is, and what applications it is commonly used in. Contrast "conduit" against raceways and wire trays.

Notes:

If you happen to have pieces of conduit available for demonstration, show them to your students during discussion time. Better yet, take them to a place where they can see electrical conduit in use!

Be sure to ask them questions about the other methods (raceways, wire trays) of laying wire, and how these methods compare with rigid conduit.

Question 11:

What is a busbar?

Notes:

Ask your students to describe possible applications for busbars. Where would they typically encounter such huge conductors of electricity?

Question 12:

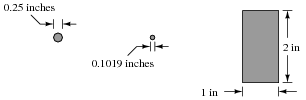

The cross-sectional area of wires is often measured in units of circular mils rather than square inches or other common area units. Explain how the "circular mil" is defined, and how it is calculated for round wires.

Notes:

Explain how this is analogous to the ßquare inch" being defined as the area of a square measuring one inch on a side. If you need to approach the definition in smaller conceptual steps, you might want to first define what a "circular inch" is before you define what a "circular mil" is.

Question 13:

Determine the cross-sectional area of these conductors (viewed from one end), in units of ßquare inches" as well as "circular mils":

|

|

| XXXXXXXX | XXXXXXX | XXXXXXX |

| 0.049 in2 | 0.008 in2 | 2.0 in2 |

| 62,500 cmil | 10,384 cmil | 2,546,479 cmil |

Notes:

Calculating the cross-sectional area of the 1 ×2 busbar in units of circular mils may be challenging for some students, because an equation directly relating linear dimensions to circular mil area may not be easy to obtain. However, even in the event that no equation can be found, there is a way to solve for the busbar's area in units of circular mils by observing the answers obtained for the other two conductors' areas.

Question 14:

Small electrical wires are almost always sized by gauge rather than by circular mils (cmils). So, if you had to calculate the resistance of a length of 22-gauge copper wire and did not have the proper tools to measure the wire's diameter, how could you find the equivalent cross-sectional area in circular mils so as to use the equation R = [(rl)/A]?

Notes:

Show your students a wire gauge table, if their textbooks do not already contain one.

Question 15:

If an electric drill is plugged into a very long extension cord instead of being plugged directly into a power receptacle, what will happen to the drill's performance? Explain your answer, with reference to Ohm's Law.

Challenge question: draw an equivalent schematic diagram showing the resistance of the extension cord conductors as resistors with the labels Rwire1 and Rwire2.

Notes:

Students who have worked with power tools, especially on construction sites where long extension cords are commonly used, will be familiar with this phenomenon. Ask your students what effect different gauges of wire in the extension cord would have on this degradation of drill motor performance. Also, ask about different lengths of extension cord. What, exactly, is the electrical quantity that varies with these dimensional changes, that causes the drill motor performance to vary?

Question 16:

Find a piece of wire or electrical cable and bring it with you to class for discussion. Identify as much information as you can about your conductor prior to discussion:

- �

- Gauge

- �

- Ampacity

- �

- Voltage rating of insulation

- �

- Temperature rating of insulation

- �

- Insulation type (plastic, Teflon, silicone, etc.)

- �

- Insulation service (conduit, wireway, direct burial, etc.)

Notes:

The purpose of this question is to get students to kinesthetically interact with the subject matter. It may seem silly to have students engage in a ßhow and tell" exercise, but I have found that activities such as this greatly help some students. For those learners who are kinesthetic in nature, it is a great help to actually touch real components while they're learning about their function. Of course, this question also provides an excellent opportunity for them to practice interpreting component markings, use a multimeter, access datasheets, etc.