Home » Circuits

Car Battery Failure Detector

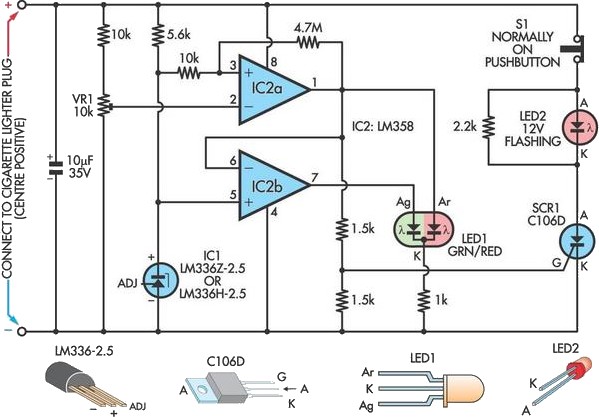

A car battery deteriorates in use and its life seldom exceeds four years. When new, its voltage may drop to only 2V while cranking the engine. As the battery ages, its internal impedance increases and so the voltage drop while cranking also increases, until ultimately the drop is high enough to prevent the engine from starting. This gradual increase in voltage drop while cranking can be used as an early warning of looming battery failure and so this circuit triggers an alarm when the battery voltage drops to 8V during cranking. IC1 is a precision 2.5V device used as the reference for two comparators based on IC2, an LM358 dual op amp.Circuit diagram:

IC2a monitors the voltage from trimpot VR1 and normally its output at pin 1 will be low while the output of IC2b will be high and LED1 will be green. When pin 2 of IC2a falls below pin 3, its output at pin 1 will go high to drive the red section of LED1 to indicate a fault. At the same time, IC2b inverts the signal from pin 1 and its output at pin 7 goes low and turns off the green section of LED1 to indicate a fault. Since the battery voltage drop occurs momentarily while cranking, a more permanent indication of the fault is provided by flashing LED2. When IC2a’s output goes high momentarily, the SCR is latched and LED2 flashes and can only be deactivated by pressing pushbutton S1.

Author: Victor Erdstein - Copyright: Silicon Chip Electronics